Bryant Racing commissioned two independent labs to conduct double blind “rotating beam” and other tests. The results prove that the post nitride “as shipped” properties of deep case S132 are lower than that of the standard Bryant prepared steel.

Ultimate Tensile Strength (UTS) of Bryant/S132 as shipped:

Bryant = 193,000 psi (193 ksi = 1331 MPa)

S132 = 181,000 psi (181 ksi = 1250 MPa)

.2% Yield Strength of Bryant/S132 as shipped:

Bryant = 179,000 psi (179 ksi = 1234 MPa)

S132 = 153,000 psi (153 ksi = 1060 MPa)

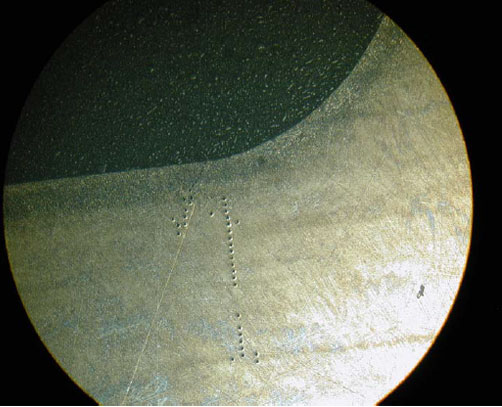

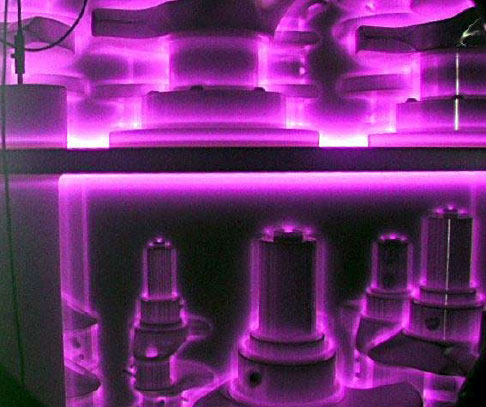

Ion Plasma nitriding is widely used for providing a hard (64HRC), thin surface on crankshafts for wear resistance for soft, oil pressure fed shell bearings. Bryant’s proprietary nitriding protocols are designed to have no effect on the core properties of our special alloys. In fact, as nitriding is the last manufacturing step, the procedure does act as a double temper.

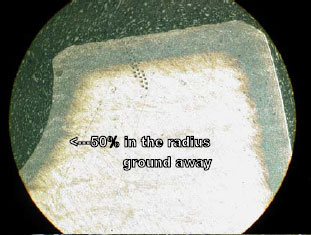

Bryant Racing began manufacturing crankshafts in 1982. Initially, Bryant used the norm at that time…gas deep case nitriding…performed “by others”, and so had encountered the many problems associated with post grinding. It was also thought the steel used at that time needed the compressive strength that deep case provided.

After a few years of doing the “norm”, Sonny Bryant developed these basic goals: incorporate into the alloy the mechanical properties needed to carry the load without having to add deep case nitride to compensate for alloy deficiencies.